Waiting Lines

What appears below is the

first model in the book (from Chapter 2, Section 1). This model is very simple; much more

elaborate models are possible. The

goal here is just to give you a feel for how SimQuick works. Explanations of the details (including

an introduction to simulation) can be found in the book.

Example: A bank

Consider the following

process within a small bank: Customers enter the bank, get into a single line,

are served by a teller, and finally leave the bank. Currently, this bank has one teller

working from 9 a.m. to 11 a.m. Management is concerned that the wait in

line seems to be too long. Therefore, they are considering two process

improvement ideas: adding an additional teller during these hours or installing

a new automated check-reading machine that can help the single teller serve

customers more quickly.

What should management do?

To answer this question,

management has collected and summarized some data:

The

amount of time between arrivals of customers can be approximated by an exponential

distribution with a mean of 2 minutes.

The line in this bank can only hold 8 people and if a person arrives

when the line is full, he/she does not get in line. The service time by the teller can be

approximated by a normal distribution with a mean of 2.4 minutes and a standard

deviation of .5 minutes.

Building the model

Next we see how to build a

SimQuick model for the current process with a single teller.

SimQuick provides five

building blocks, called Elements, which can be combined in a huge number of

ways. The elements are Entrances,

Exits, Buffers, Workstations, and Decision Points.

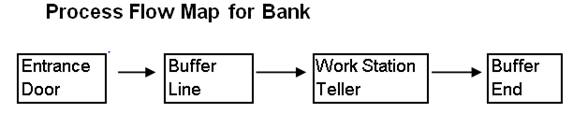

The first step in using

SimQuick is to draw a flow map of the real-world process using these building

blocks. Here’s what the model

looks like for the bank:

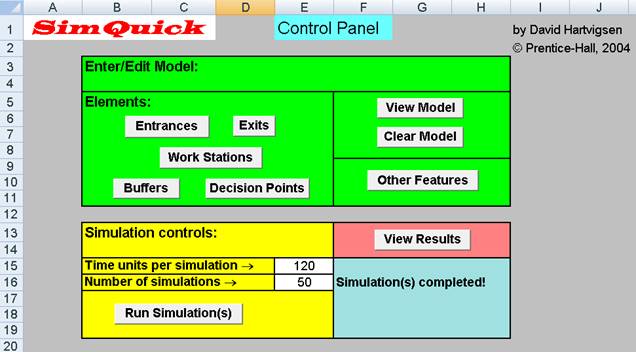

The next step is to input

the model into SimQuick in Excel.

You first open the Excel file SimQuick-v2.xls. What you see is the Control Panel, which

is copied below. For each element

in the model, you click on the element’s button on the Control Panel and

fill in a table with the details about the element. You also fill in, on the Control Panel,

how many simulations you want to do and how long each simulation should last. (In this example, we are doing 50

simulations, each for 120 time units, which corresponds to two hours.) The filled-in Control Panel and tables

look like this:

Running and analyzing the model

You then click Run

Simulations on the Control Panel. It

takes SimQuick just a few seconds to simulate the 9AM to 11AM time period at

the bank 50 times. Clicking on View

Results brings up the table below.

(Here we see only the results of the first five simulations.)

|

Simulation

Results |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Element |

Element |

Statistics |

Overall |

Simulation number(s) |

||||

|

types |

names |

|

means |

1 |

2 |

3 |

4 |

5 |

|

|

|

|

|

|

|

|

|

|

|

Entrance(s) |

Door |

Objects entering process |

53.88 |

58 |

56 |

55 |

57 |

48 |

|

|

|

Objects unable to enter |

6.70 |

7 |

3 |

6 |

18 |

0 |

|

|

|

Service level |

0.90 |

0.89 |

0.95 |

0.90 |

0.76 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

Work Station(s) |

Teller |

Final status |

NA |

Working |

Working |

Working |

Working |

Not Working |

|

|

|

Final inventory (int. buff.) |

0.00 |

0 |

0 |

0 |

0 |

0 |

|

|

|

Mean inventory (int. buff.) |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|

|

|

Mean cycle time (int. buff.) |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|

|

|

Work cycles started |

48.43 |

51 |

49 |

49 |

50 |

48 |

|

|

|

Fraction time working |

0.96 |

0.98 |

1.00 |

0.97 |

0.97 |

0.96 |

|

|

|

Fraction time blocked |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|

|

|

|

|

|

|

|

|

|

|

Buffer(s) |

Line |

Objects leaving |

48.43 |

51 |

49 |

49 |

50 |

48 |

|

|

|

Final inventory |

5.45 |

7 |

7 |

6 |

7 |

0 |

|

|

|

Minimum inventory |

0.00 |

0 |

0 |

0 |

0 |

0 |

|

|

|

Maximum inventory |

7.77 |

8 |

8 |

8 |

8 |

7 |

|

|

|

Mean inventory |

4.47 |

5.03 |

4.64 |

3.05 |

6.43 |

3.42 |

|

|

|

Mean cycle time |

11.04 |

11.83 |

11.36 |

7.46 |

15.43 |

8.54 |

|

|

|

|

|

|

|

|

|

|

|

|

End |

Objects leaving |

0.00 |

0 |

0 |

0 |

0 |

0 |

|

|

|

Final inventory |

47.44 |

50 |

48 |

48 |

49 |

48 |

|

|

|

Minimum inventory |

0.00 |

0 |

0 |

0 |

0 |

0 |

|

|

|

Maximum inventory |

47.44 |

50 |

48 |

48 |

49 |

48 |

|

|

|

Mean inventory |

22.75 |

22.84 |

24.19 |

22.71 |

23.29 |

22.89 |

|

|

|

Mean cycle time |

Infinite |

Infinite |

Infinite |

Infinite |

Infinite |

Infinite |

From this table you can

see two key performance measures: Our simulated customers were waiting in line

for 11.04 minutes, on average (see the “Mean cycle time” row under

“Buffer(s), Line”), and there were 4.47 customers in line, on

average (see the “Mean inventory” row under “Buffer(s),

Line”).

From here it’s easy

to change the model for the case of two tellers and the case of a single teller

who can work faster due to some automation. We can then see the effect of these

changes on the waiting time and number of customers in line. This can help management decide what to

do.

See the book for the

details.